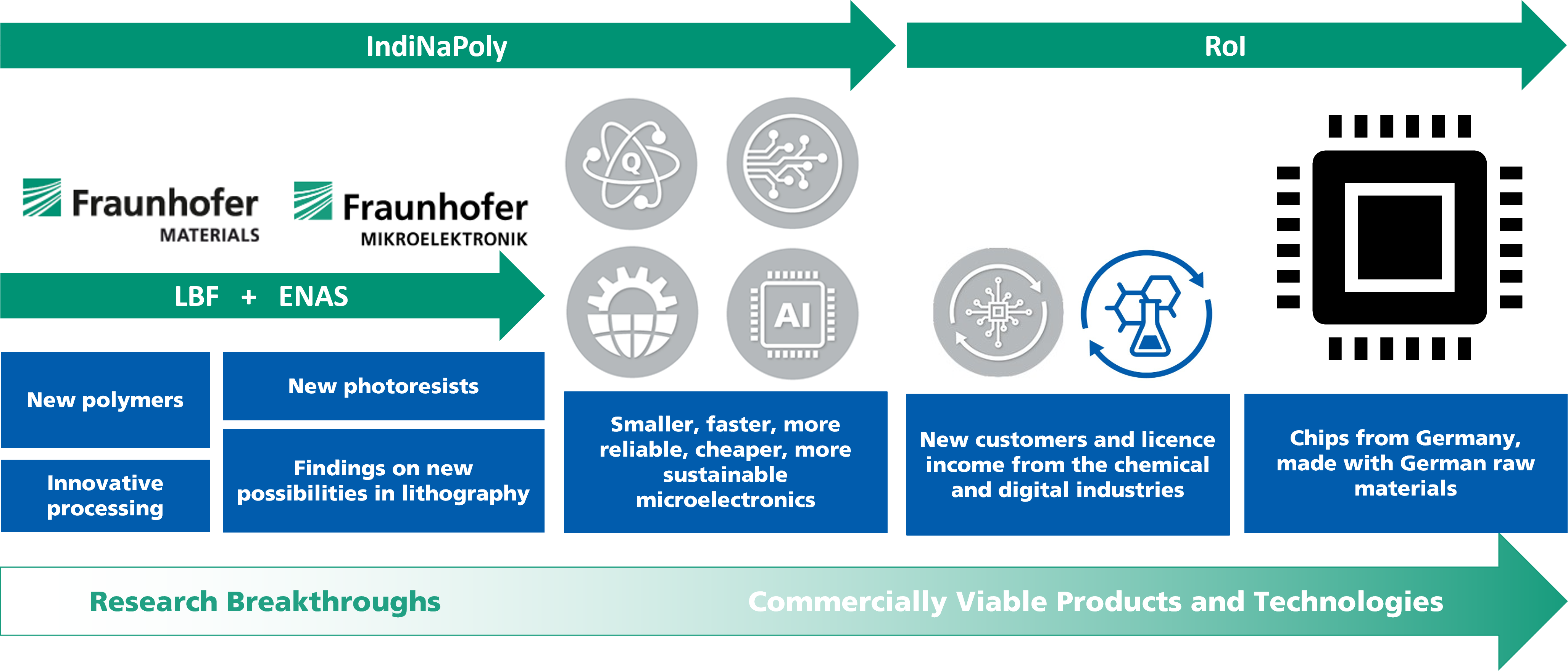

Fraunhofer-Prepare-Project IndiNaPoly

Advances in e-beam lithography

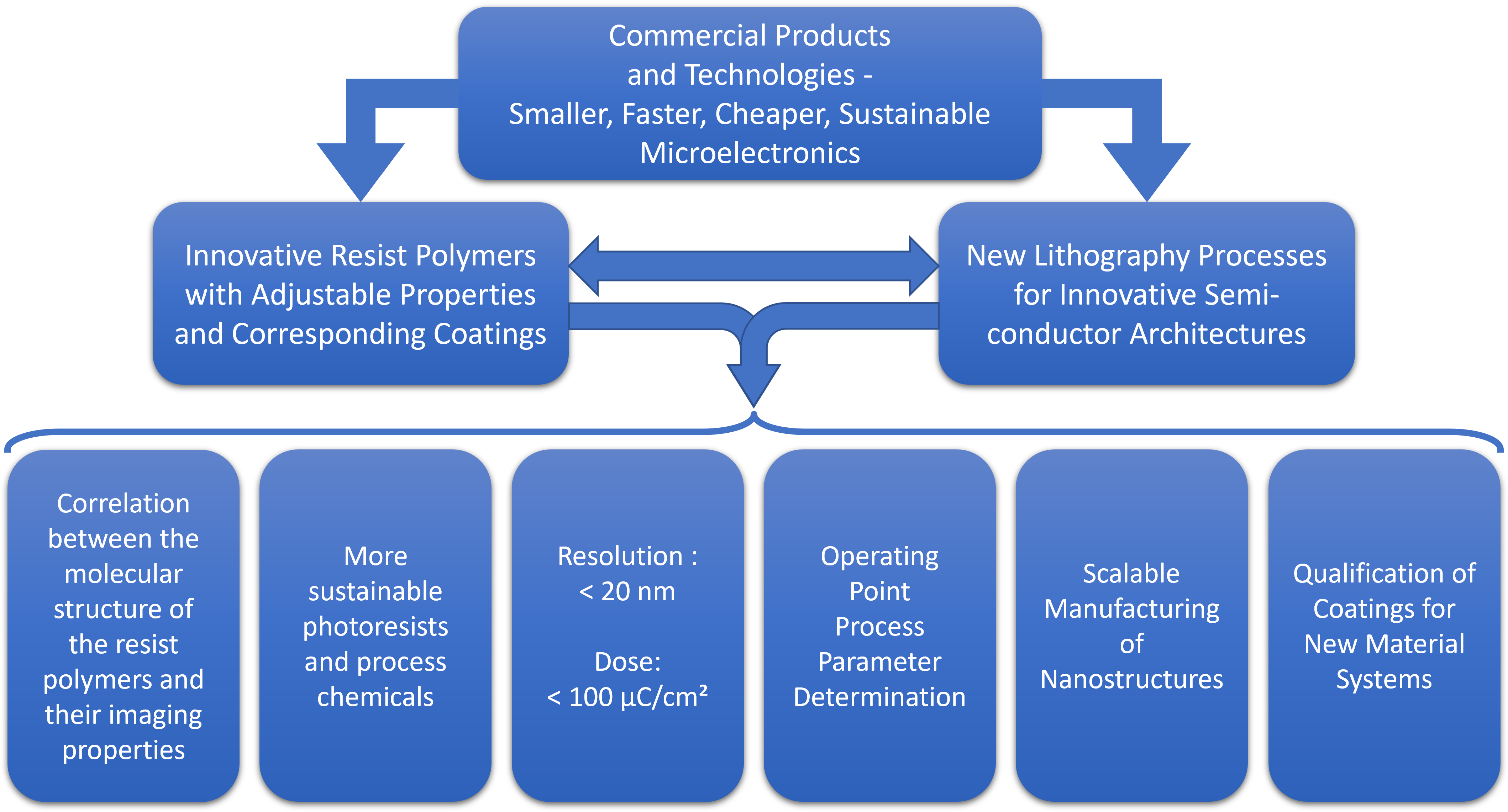

The IndiNaPoly project aims to close the gap between sensitivity and resolution in e-beam lithography. Our focus is on making this technology usable for the production of chips in medium quantities of 1,000 to 100,000 per year.

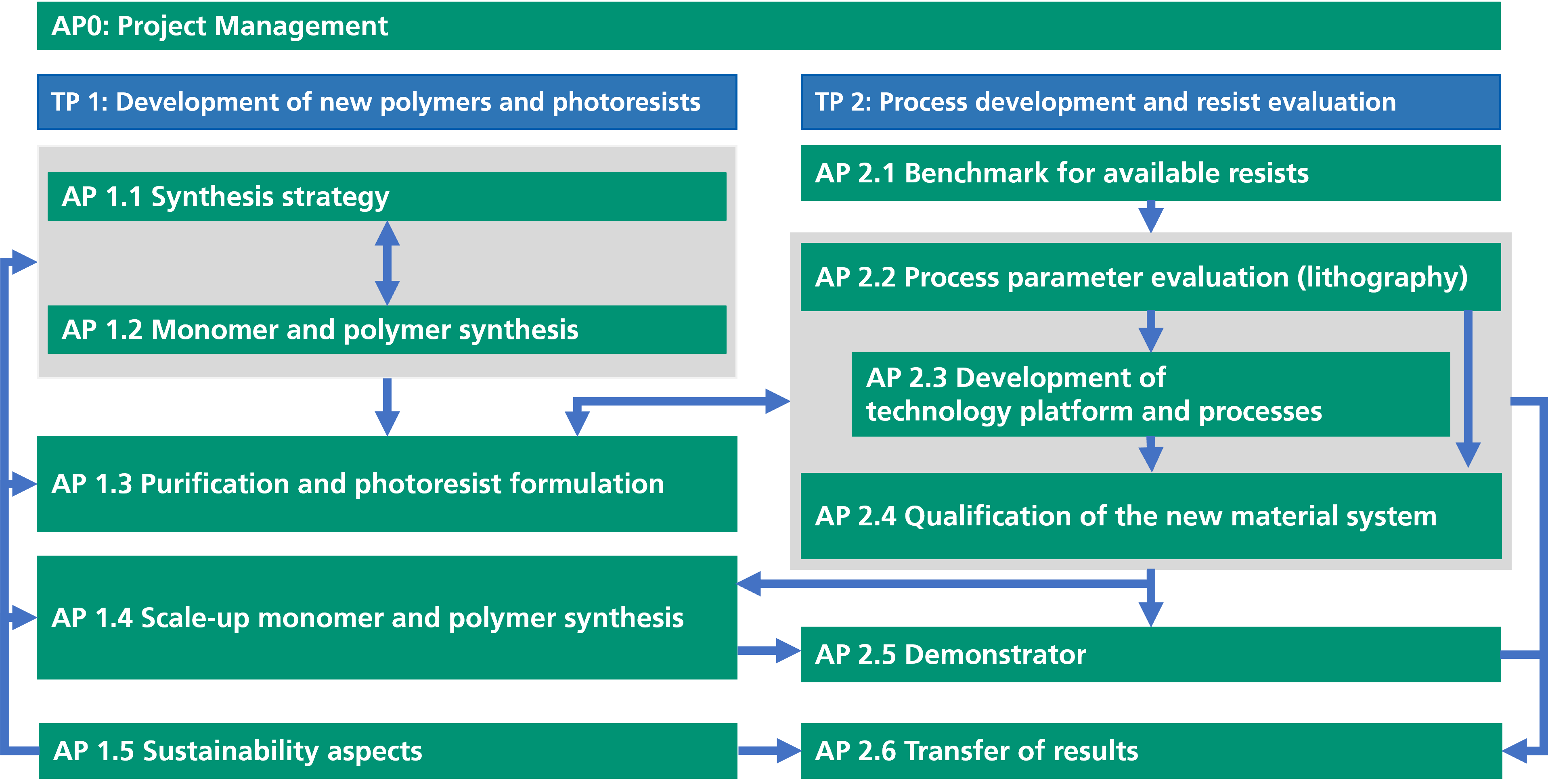

By individually adapting the binder polymer according to a modular principle and coordinating the lithographic process steps with the respective polymer, we are developing a better understanding of the relationship between polymer structure and imaging properties. This should lead to the development of new resists that achieve resolutions of less than 20 nm with 6 to 7 times higher sensitivity.

In addition, shorter process cycles contribute to energy savings and a reduction in the carbon footprint. We are also examining sustainability aspects such as the substitution of fossil-based process chemicals and the recyclability of production waste.

In a highly competitive environment in which countries such as China and Taiwan are investing heavily in semiconductor technologies, the German semiconductor industry is dependent on continuous investment in research and development. The IndiNaPoly project represents an important step toward making the production of microelectronic components more efficient and cost-effective.

The collaboration between the Fraunhofer institute for Structural Durability and System Reliability LBF and the Fraunhofer institute for Electronic Nano Systems ENAS is crucial for the implementation of these innovative approaches.

Fraunhofer with its institutes LBF and ENAS

Fraunhofer with its institutes LBF and ENAS